PDLC SMART GLASS

PDLC (Polymer Dispersed Liquid Crystal) smart glass is a technology that utilizes an electrochromic film to switch between transparent and opaque states, offering controllable privacy and light transmission in architectural and automotive applications.

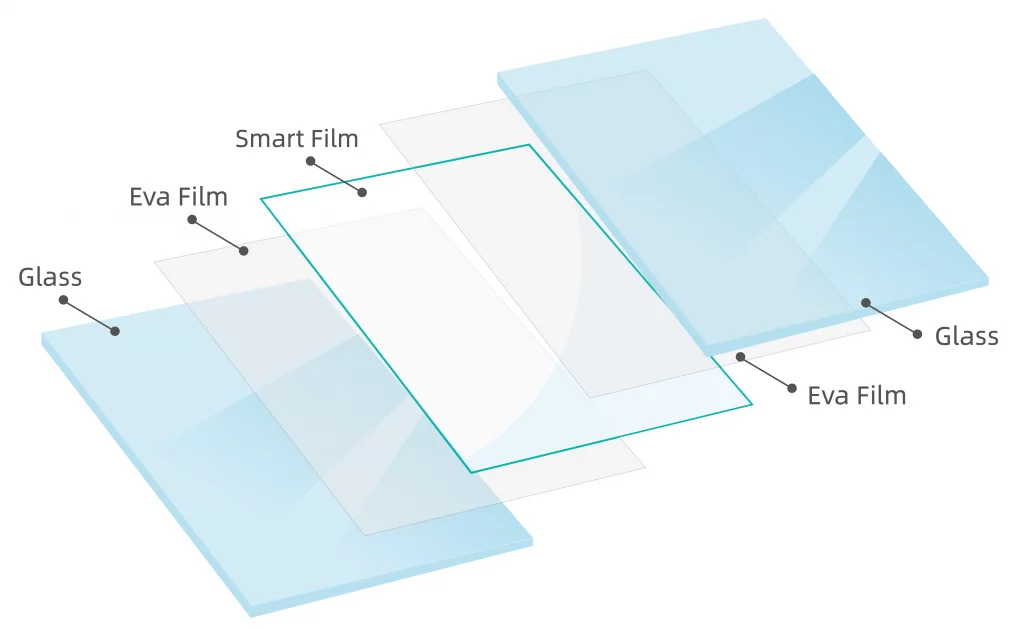

Smart glass is a new type of glass with a sandwich structure that combines PDLC film between two layers of glass and is integrally formed after high temperature and high pressure bonding. Through the controller, it can instantly switch between opaque and transparent.

UV Protection:

Smart glass can block harmful ultraviolet (UV) rays, protecting interiors and occupants from potential damage.

Privacy Control:

Smart glass can switch between transparent and opaque states, offering instant privacy when needed.

Energy Efficiency:

By adjusting transparency, smart glass can regulate sunlight and reduce the need for artificial lighting and cooling.

Noise Reduction:

The insulating properties of this glass also help in dampening external noise, creating a quieter and more serene environment indoors.

Aesthetics:

Smart glass enhances interior design by providing a sleek, modern look and the ability to transform spaces dynamically.

Space Optimization:

Smart glass can create flexible, multifunctional spaces by instantly dividing or merging areas as required.

How It Works

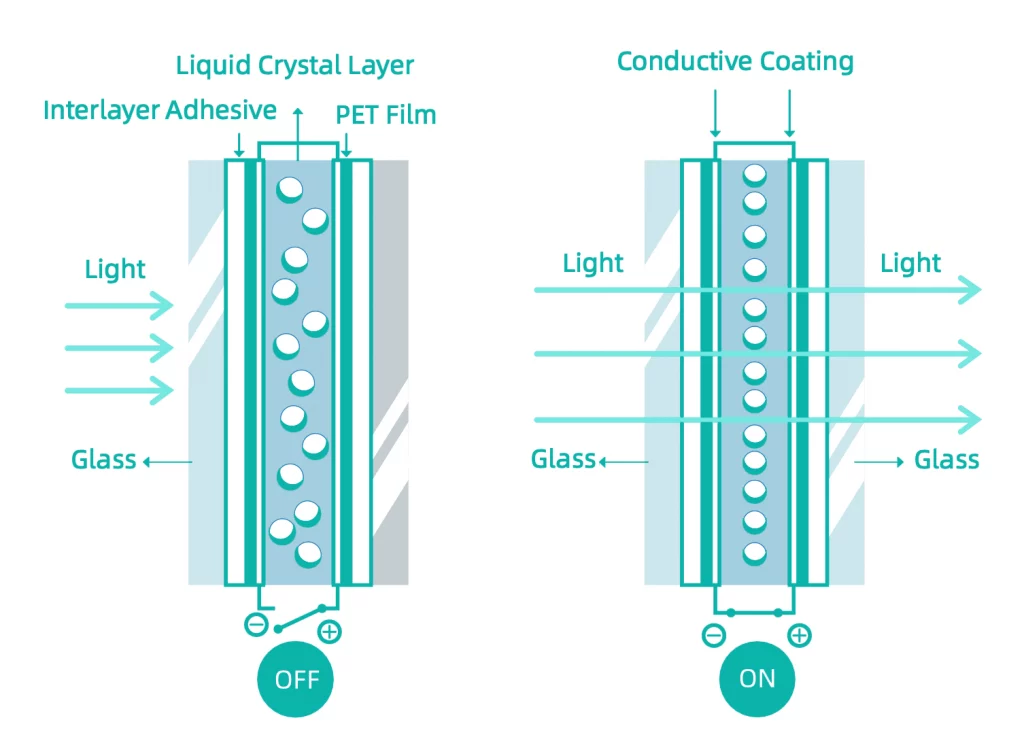

PDLC laminated glass integrates Polymer Dispersed Liquid Crystal (PDLC) technology with the safety benefits of laminated glass. Comprising multiple layers of glass sheets, a PDLC film with dispersed liquid crystal droplets is sandwiched between them. Transparent conductive layers, acting as electrodes, are applied to the surfaces facing the PDLC layer. An interlayer film bonds the glass layers, providing structural integrity and safety. When an electric voltage is applied, the liquid crystal droplets align, allowing light transmission and rendering the glass transparent. In the absence of voltage, the droplets scatter, making the glass opaque. The laminated structure enhances safety by preventing glass fragments from scattering upon breakage. This combination of dynamic transparency control and safety features makes PDLC laminated glass valuable in applications like architectural windows and automotive windshields.

Covert Vision Control system

Effortlessly command your surroundings. Easily manage your panels using the provided control systems below.

Why Covert Vision ?

Our Product

- Lowest haze industry wide

- Fast switching time of 0.1 seconds

- Low voltage power consumption

- Lifetime over 18 million+ on/off cycles

- Over 10,000 consecutive ‘On’ hours

- Fully customizable dimensions, shapes, patterns

- All day transparency with patented controllers

- Manufactured in ISO 9001 compliant facilities worldwide

- CE and UL certified hardware

- Touch Panels and RF Remotes

Our Company

- Leading with the latest in PDLC technology for dynamic applications.

- Custom PDLC applications designed for diverse industries and spaces.

- Skilled professionals ensuring reliability and high-performance PDLC solutions.

- Effortless upgrade of existing spaces with our PDLC products.

- From smart glass to privacy films, our PDLC solutions meet various needs.

- Rigorous quality control for durable and top-performing PDLC products.

- Continuous innovation at the forefront of PDLC advancements.

- Understanding and exceeding client expectations for long-term partnerships.

- Eco-friendly practices in PDLC manufacturing for a greener future.